Moretti has been around since the post-war period, but since 1979 we have focused on designing and manufacturing clamping systems for machine tools at our current premises in Villa Guardia.

Our clamping systems ensure a firm hold throughout the machining process, preventing movement and minimising vibration due to interaction with the tool, to ensure maximum compliance with the required technical specifications and minimise the possibility of defects or inaccuracies.

Easy to use, with very low maintenance requirements and suitable for even the most advanced machining operations, our clamping solutions guarantee repeatability and safety.

Our clamping systems are modular and the range is wide, because we know that there is no such thing as a standardised clamping solution for all workpieces.

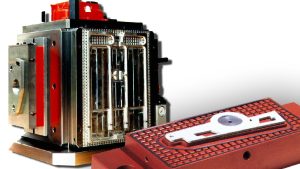

In addition to traditional mechanical clamping systems, we also produce vacuum clamping solutions with a suction plate which, using vacuum technology, allow the machining of non-magnetic materials on 5 sides.

We pay constant attention to the evolution of materials and technologies, to offer you the best in terms of quality and precision, so that you can always keep up with the highest quality standards.

Thanks to our wide range of products, it is possible to achieve optimal clamping with reduced tooling times and to exploit the full potential of your machinery. However, if the solutions in the catalogue or existing module combinations do not meet your requirements, we are always ready to create a customised clamping solution for your particular combination of materials, dimensions and processes.

Dedicated solutions

designed and manufactured quickly according to your requirements and technical specifications

Clamping systems with vacuum plate

efficient and safe clamping for the mechanical machining of non-magnetic materials

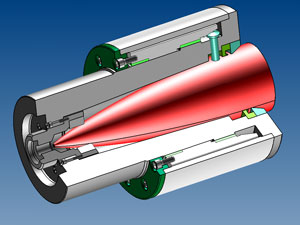

Clamping and fastening systems

for flexible, precise and repeatable machining of all magnetic materials