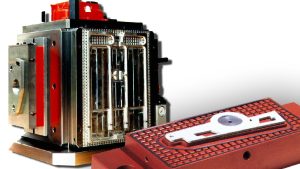

If you are interested in clamping systems for mechanical machining which provide a guarantee of precision, flexibility, repeatability and safety, Moretti’s modular solutions are what you are looking for.

Our clamping systems are simple to use and maintenance-free, but they are perfectly suitable for the most advanced and complex technologies, including CNC mechanical machining.

Discover now our mechanical clamping and fastening systems (if you are interested in VACUUM fastening click here): our range is very wide and divided into Cubes, Plates, Towers, Crankwebs, Pallets, Over-pallets and Overlays.

Click on the box you are interested in to find out about the characteristics of our offer, from the materials in which the different clamping solutions can be made, to the dimensions of the workpieces which can be machined with each module.

We will be happy to combine several modules or design and implement clamping solutions with special shapes and sizes tailored to your requirements.

Should you still have any doubts about the most suitable material for your clamping requirements, we would be happy to advise you without obligation on the most suitable clamping solution in the material best suited to your needs: write to our technical department at utc@morettimodulare.it or contact us on +39 031.480.782

EQUIPMENT

Grid solutions

To ensure maximum flexibility in machining operations with frequent changes of workpieces, our grid solutions are optimal: you can quickly create a new clamping structure and change it in no time whenever necessary.

Dedicated plates

For machining operations which recur periodically, the ideal solution is the system with dedicated inset plates, which can be fixed with screws or zero-point systems: we can create one B for you, with an a purposely-built tool magazine, to be instantly ready as soon as the need arises.

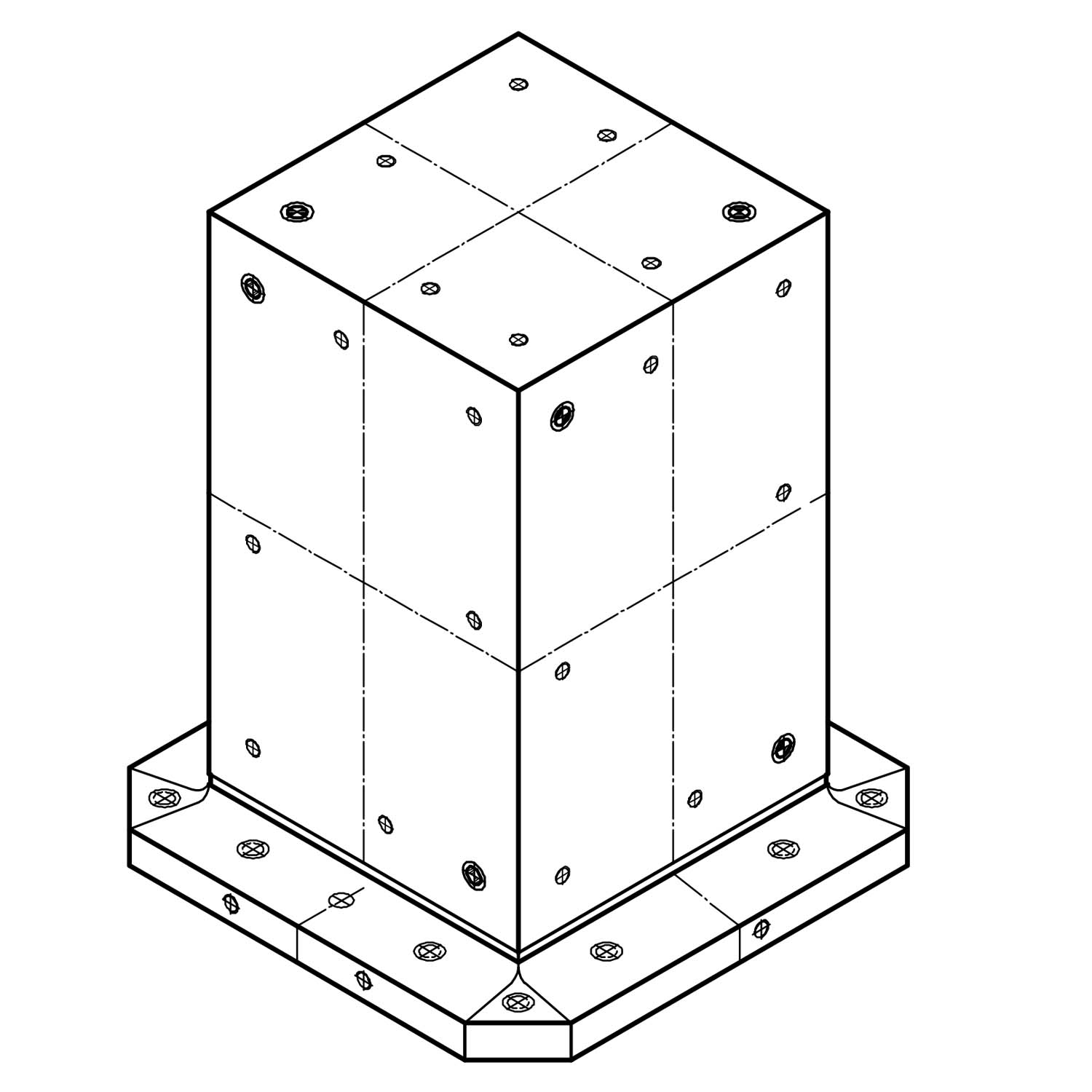

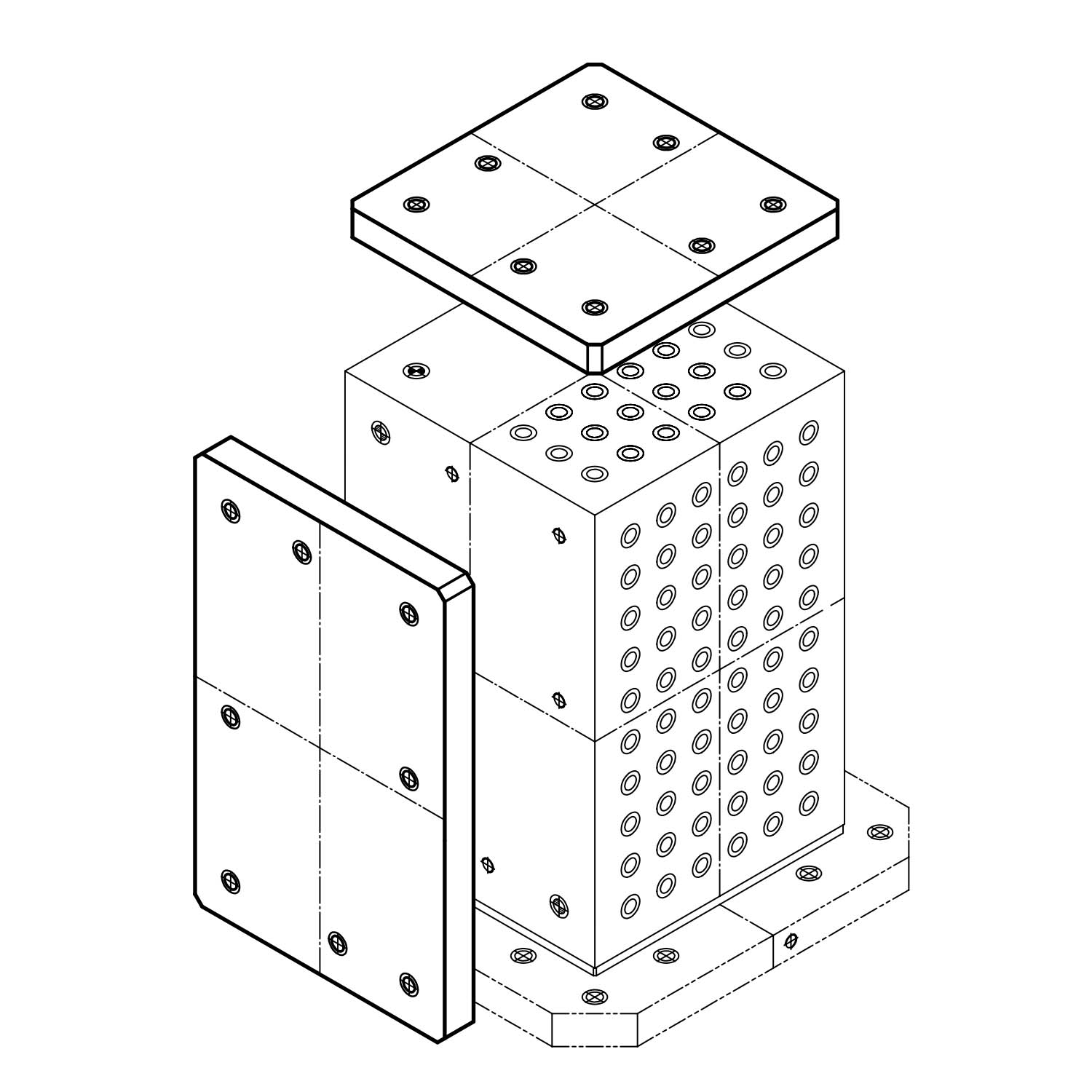

Clamping cubes

Modular and customisable, our clamping cubes can be combined with each other or with other shapes: on request we can also make them to measure.

Geometries

- quadrangular

- rectangular

- with four or five sides

- with grid or plate holder

Dimensions

from 250 x 250 mm

to 550 x 850 mm

Materials

- grey cast iron

- aluminium

- Granisint

Clamping plates

Our main body plates are available in a wide range of formats and you can choose between steel or aluminium base plates and grid plates.

Upon request, they can be customised according to the type of machining to be carried out.

Available with

- holes for calibrated screw fixing

- grid

Materials

- aluminium

- grey cast iron

- steel

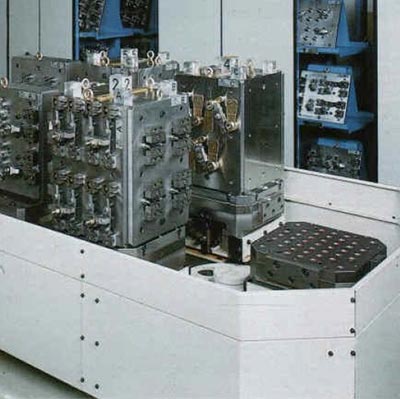

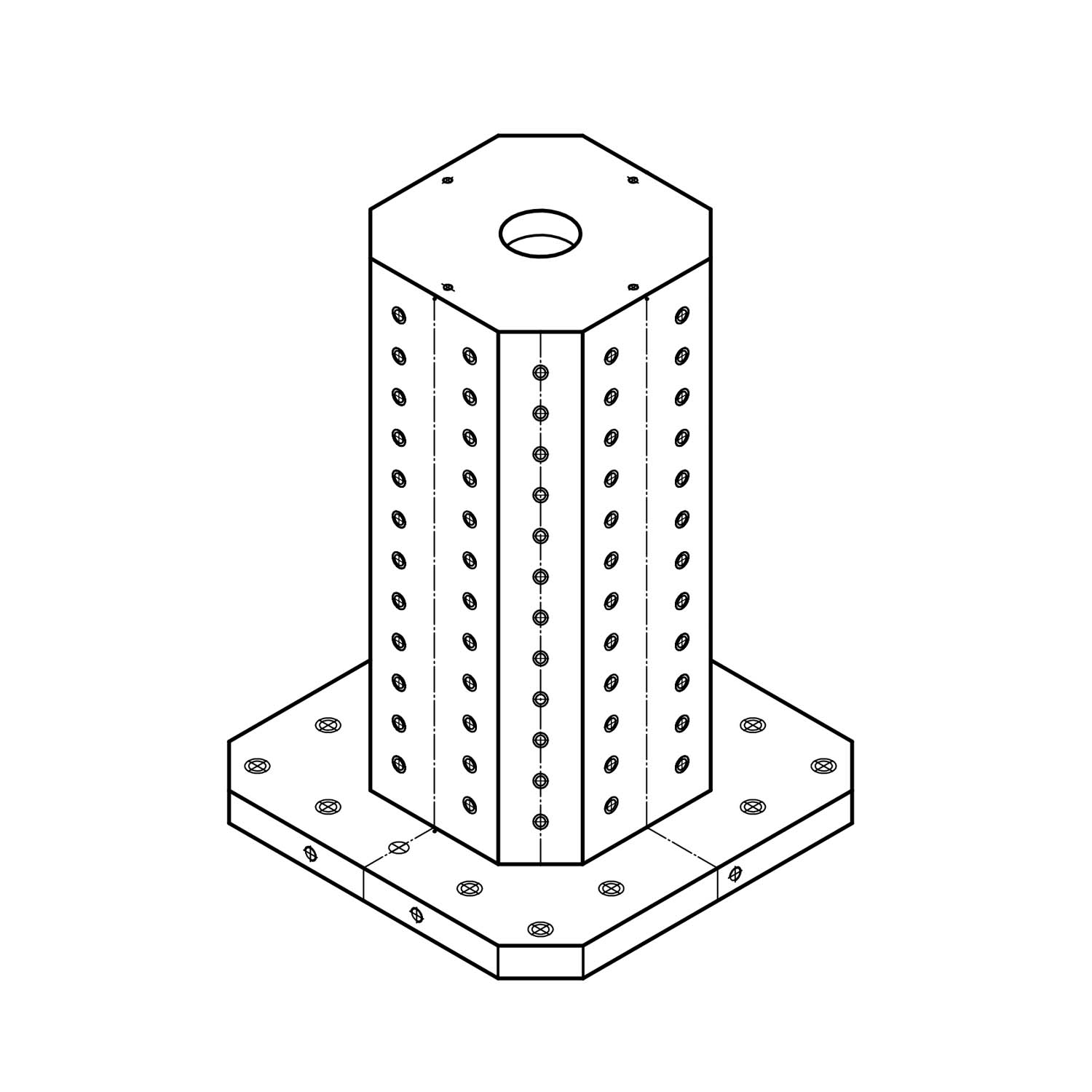

Towers for multiple clamping

Our multiple clamping towers are available in different standard heights; we make customised towers on request for special machining operations.

Geometries

- three- or four-sided

- bivalent eight-sided

- bivalent cross-shaped

Height

- from 452 mm (+base 40 mm)

- to 950 mm (+base 40 mm)

Materials

- grey cast iron

- aluminium

- Granisint

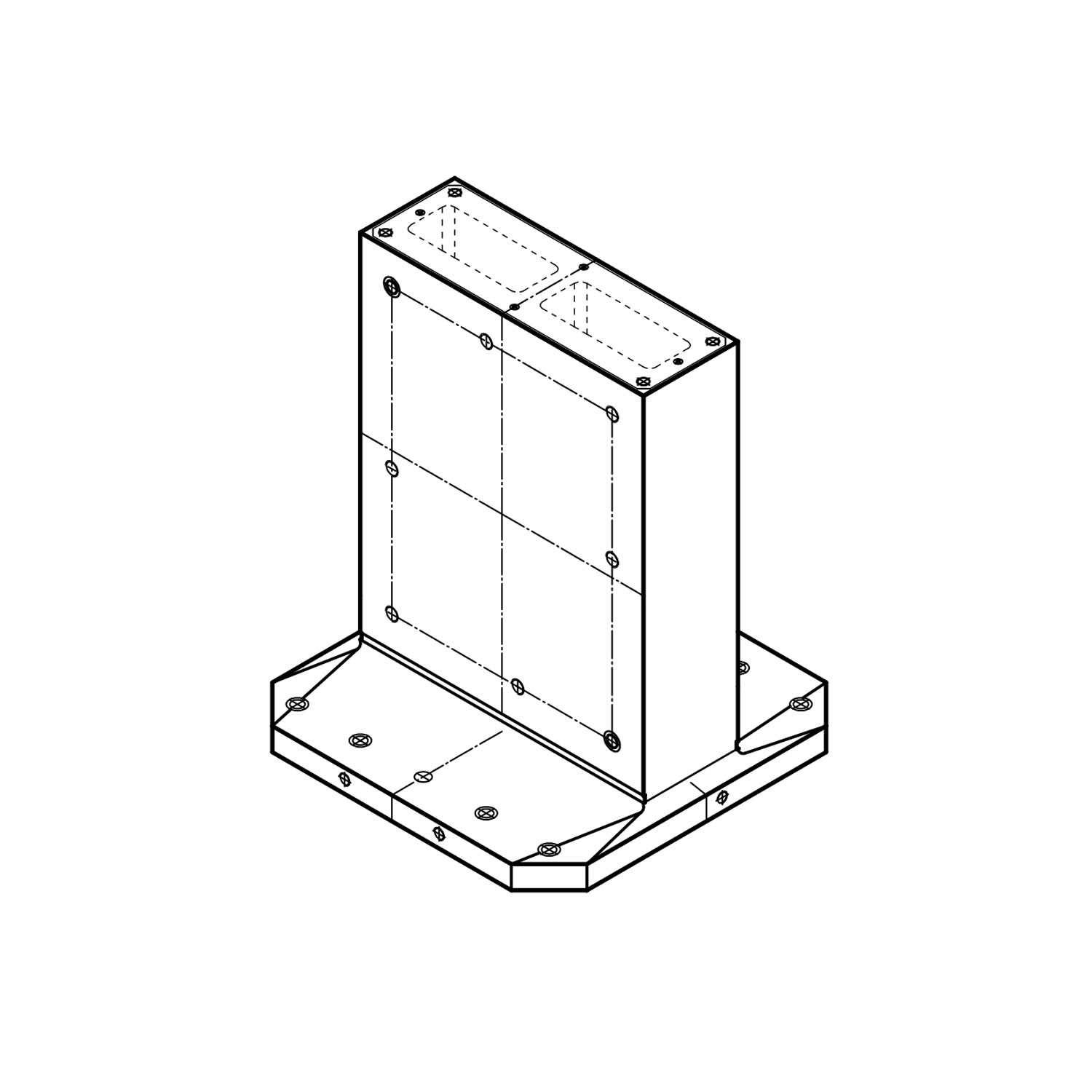

Clamping crankwebs

Our clamping crankwebs are available in numerous versions: we can help you choose the most suitable for the type of mechanical processing you are interested in.

Geometries

- double-walled plates (with grid or plate holder)

- two-sided oversize plates (with grid or plate holder)

- angle plates with shelf (with grid or plate holder)

- angle plates (with grid)

- sine plates (with grid)

Dimensions

- from 250 x 350 mm

- to 1050 x 1050 mm

- height: up to 1000 mm

Materials

- grey cast iron

- aluminium

- Granisint (only for the double-walled versions)

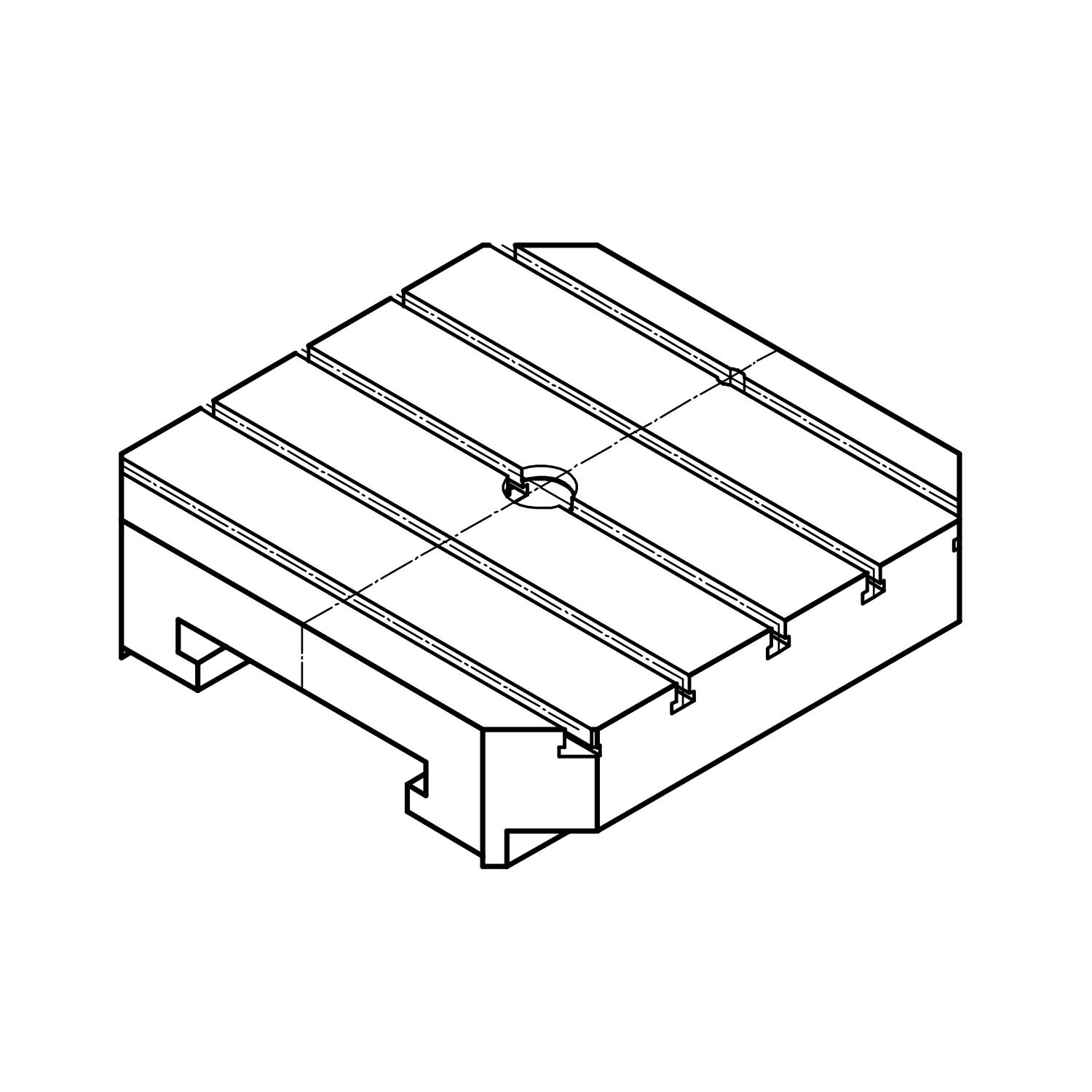

Pallets and Overlays

We can provide you with a wide range of pallets, over-pallets and overlays in different geometries, sizes and materials; we can design specific solutions for you.

Geometries:

- Quadrangular (max dimensions1000 x 1000 mm)

- Rectangular (max dimensions 1200 x 550 mm)

- Circular (max diameter 600 mm)

Available with:

- T-slots

- calibrated grid

Materials:

- grey cast iron

- aluminium

MATERIALS

Our clamping solutions are available in different materials to best suit your requirements.

Granisint

The mineral agglomerate known as synthetic granite or Granisint combines the typical lightness of aluminium alloys with the vibration dampening capacity of cast iron, improving on both. Read on…

Even lighter than aluminium, it provides an almost nine-fold reduction in vibration compared to cast iron; it is also characterised by high stability and low thermal conductivity, with less thermal expansion and distortion.

The lightness of the material, free from surface oxidation processes, creates less load on the structures, making it possible to support heavier parts without exceeding the maximum permissible load.

Displacement inertia is reduced; high vibration damping enables highly dynamic machining.

Cubes, towers and four-sided crankwebs are available in Granisint. Close

Grey Cast Iron

Our lamellar or grey cast iron is produced using recycled cast iron and steel, in full compliance with the principles of circular economy, with the addition of graphitising elements. Our lamellar or grey cast iron is produced using recycled cast iron and steel, in full compliance with the principles of circular economy, with the addition of graphitising elements. Read on…

The resulting material undergoes treatments which ensure excellent resistance to wear and chipping.

Its vibration dampening capacity is particularly appreciated, thanks to the presence of graphite flakes: a fundamental characteristic to improve the quality of machining, even at high speeds, increasing tool life.

The grey cast iron used to produce our components is standardised and can be surface hardened.

All our clamping solutions are available in grey cast iron. Close

Aluminium

The light metal par excellence, champion of the circular economy due to its perfect recyclability at the end of its life cycle, aluminium carries numerous advantages in terms of efficiency in handling and use: above all thanks to its specific weight, just over one third of that of most cast irons. Read on…

Corrosion resistant, thanks to its lightness it places less strain on machine structures such as guides and pallets.

All of this without compromising strength, which is ensured by the presence of special alloying agents and treatments to improve its functional properties.

For our aluminium clamping and fastening solutions, we use artificially aged casting alloy, or rolled and stabilised alloy.

Cubes, plates, towers, crankwebs, overpallets and overlays are also available in aluminium. Close

Steel

Particularly tough and resistant to corrosion and oxidation, steel is appreciated where high temperatures, processes requiring washing with aggressive detergents or environmental conditions make it necessary to resort to the proverbial strength of this material. Particularly tough and resistant to corrosion and oxidation, steel is appreciated where high temperatures, processes requiring washing with aggressive detergents or environmental conditions make it necessary to resort to the proverbial strength of this material. Read on…

For our clamping and fastening solutions we use various types of steel: standard construction steel, carbon steel and special heat-treated, case-hardened and tempered steels.

The best part of our steel clamping systems for mechanical machining are available with surface hardening and burnishing treatments. Close

Which material is best?

Compare the main physical properties of the materials used to manufacture our clamping systems and choose the most suitable one for your machining operations.

| material | density kg/dm3 | log decrease (vibration dampening) | thermal linear expansion coefficient | tensile strength N/mm2 | thermal

conductivity W/mK |

|---|---|---|---|---|---|

| GRANISINT synthetic granite | 2,4 | 0,035 | ca. 12 x 10-6 | 15-20 | ca. 2 |

| Grey Cast Iron GG20 | 7,1-7,3 | 0,004 | ca. 10 x 10-6 | 200-400 | ca. 50 |

| Aluminium light alloy | 2,76 | 0,0004 | ca. 23 x 10-6 | 470-520 | ca. 140 |

| Steel | 7,5-8 | ca. 17 x 10-6 | ca. 52 |