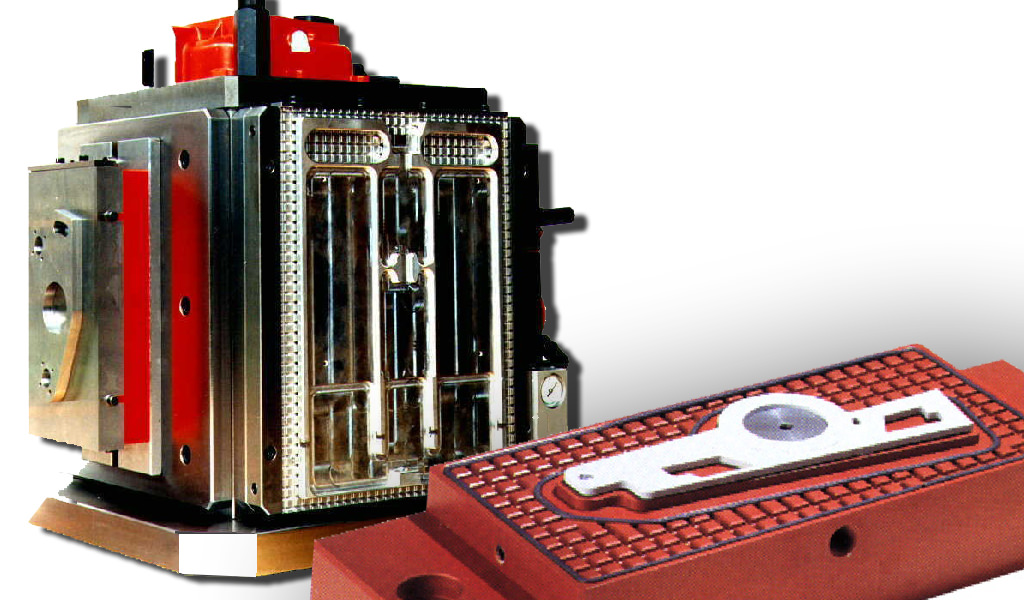

Moretti clamping solutions with vacuum plate

Published on: 02/11/2021

Moretti’s Product Specialist for Vacuum Solutions, Paolo, describes the features of these systems and the advantages obtained by using them.

For which types of machining are Moretti vacuum solutions most commonly used?

Vacuum solutions are mainly used for non-magnetic materials, as long as they are not porous. They are ideal for processing plates in aluminium, titanium, plastic, graphite, brass and many other materials.

This particular clamping technology enables five-sided machining and fast clamping (in just a few seconds), reduces the risk of workpiece deformation and results in less scrap, which in the case of materials with high intrinsic value is a great advantage.

Specifically, which types of clamping systems are most suitable for certain processes?

Our range includes different types of plates:

- The standard plates have a grid pitch of 10 to 25 mm; they are suitable for most machining operations, particularly chip removal.

Vacuum clamping maximises its potential by preventing movement along the vertical plane. - Plates with micro-holes or ribs distribute the clamping force over the entire area of the workpiece, thereby eliminating the risk of deformation; they are ideal for machining thin workpieces which could be damaged by traditional fixtures.

- Our Total Block plates combine the possibility of mechanical and vacuum clamping: all advantages in one solution, which is therefore also suitable for composite materials.

In certain cases, such as through machining, we propose the use of dedicated overplates: besides allowing great flexibility in tooling, so that machining can start very quickly as soon as the request arises, they protect the Vacuum plate from drilling, allowing the workpiece to be drilled without any problems.

Vacuum solutions include different vacuum machines: which are the most frequently used in the different segments?

Let’s start with the Mini-Units, our basic vacuum creation machines; ideal for dry machining of small workpieces (within 300 mm), they are widely used for engraving plaques.

All controls can be operated directly from the machine simply and intuitively.

The Units can process even medium-sized workpieces (up to about 600 mm) and thanks to wireless controls can be controlled remotely. A safety system with visual and sound alarms stops the units if there is no vacuum for any reason, preventing damage to parts and tools. A recovery tank for the lubricating and cooling liquid maintains optimal machining conditions.

Workstations allow the machining of larger parts (even several metres): they are suitable for the simultaneous management of several plates.

In addition to the possibility of remote operation and alarms in the event of malfunctioning, they are equipped with an automated system for discharging the lubricating and cooling liquid, which can be set from a PC and connected to the liquid tank, so that the appropriately filtered fluid can be reintroduced into the machining process: a great saving and an advantage for the environment.

In addition to these features, the Workstation S, with its touch screen control panel, enables uninterrupted work cycles of more than 8-10 hours; in the event of sudden drops in pressure, it is able to maintain blocking for 10-15 seconds without having to stop machining immediately.

For larger models, cleaning is easily performed with compressed air; our solutions can also be used for machining with multi-tool equipment.

What advantages do Vacuum Moretti solutions provide, in general and compared to alternatives on the market?

In actual fact, there aren’t many alternatives which can be compared to our solutions: the possibility of using numerically controlled machines, of processing such a wide range of materials practically in a continuous cycle and of managing all types of machining, even remotely, with the right mix of safety, precision and sensitivity in the case of the most valuable materials can be found in Moretti’s solutions, but from what customers tell us they are difficult to find in the same degree in other manufacturers’ systems.

That’s why our customers continue to renew their trust in us.

Could you provide an example of a segment, or a particular process, where the use of Moretti Vacuum solutions has simplified activities and brought advantages?

Our solutions are distinguished by their ability to handle even complex situations.

For example, our dedicated overplates allow the clamping of complex geometries: we created an overplate for a customer in the luxury car segment to manufacture specially shaped details, which allowed perfect clamping without deformation and easy further machining.

Another customer used our solutions for the machining of thin brass plates from which parts for spectacle frames were obtained; the elimination of the risk of deformation and the considerable reduction in waste were very important in this case.

How much does the ability to provide services affect customers when choosing Moretti Vacuum solutions?

For Vacuum solutions, we have a clear advantage in the quality of the solutions we offer: our energies are focused on aspects such as customised design and support during commissioning, certification and after-sales service.

Technological evolution also allows us to provide remote assistance, which is particularly important for customers abroad: our systems are located all over the world and where we cannot physically intervene quickly, our remote assistance proves timely and effective.

For over forty years, Moretti has been designing and manufacturing clamping equipment for machine tools. Standardised or customised, mechanical or based on vacuum technology, Moretti’s solutions meet every requirement of the manufacturing industry, guaranteeing precise and repeatable machining, flexibility and safety, with low operating costs.

For information on Moretti’s fastening solutions, the company’s technical and commercial staff can be reached on +39 031 480782 or at info@morettimodulare.it