Discover our Vacuum clamping systems (if you are interested in mechanical clamping and fastening systems click here): we offer a complete range of vacuum machines, as well as different types of plates and overlays to create the best solution for you.

Particularly suitable for machining sheet metal and other materials with thicknesses too low for standard clamping fixtures, they are ideal for non-magnetic materials such as plastic or aluminium and also allow 5-sided machining.

Our vacuum solutions also allow for complex cycles lasting more than 10 hours.

Maintenance requirements are minimal and largely solvable remotely via our telephone helpline or by using our maintenance kit.

More than 25 years of experience in the Vacuum clamping systems segment allows us to help you choose the best vacuum solution for your requirements, matching it to the ideal plate for your machining operations, even the most complex ones.

If you need help in selecting the combination which best matches your production, contact our technical department now: we can advise you on the ideal choice or, if you need a tailor-made solution, we shall design and manufacture it especially for you.

Write to us at utc@morettimodulare.it or call us on +39 031.480.782

Equipment

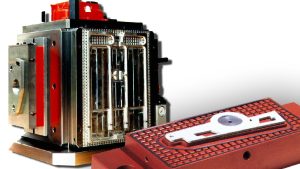

Vacuum machines

From simple, low consumption multi-stage ejector units for smaller plates to vacuum pump workstations for larger plates, all our vacuum technology solutions are easy to use and offer an excellent ratio of performance to power consumption.

Plates and Overlays

Lattice plates – standard, microperforated or ribbed – for maximum flexibility in format changeovers; combined Vacuum-mechanical plates for special requirements or composite materials; dedicated plates for periodically recurring machining operations. Discover the wide range of solutions perfectly matched to our vacuum creation systems.

Vacuum machines

From simple, low consumption multi-stage ejector units for smaller plates to vacuum pump workstations for larger plates, all our vacuum technology solutions are easy to use and offer an excellent ratio of performance to power consumption.

Mini Unit

Ideal for

- small plates (approx. 300 mm long)

- dry machining

Works with all types of plates and overlays

Unit

Ideal for

- surfaces of up to 600 mm in length

- machining operations requiring water or coolant

Equipped with fluid recovery tank

Works with all types of plates and overlays

Workstation

Ideal for

- medium or large surfaces (up to approx. 1000 mm in length)

- machining operations requiring water or coolant

Equipped with fluid recovery tank and automatic unloading when the part is released

Works with all types of plates and overlays

Workstation S

Ideal for

- medium or large surfaces (up to approx. 1000 mm in length)

- long processing cycles (more than 8-10 hours)

Equipped with fluid recovery tank

Works with all types of plates and overlays

Plates and Overlays

Lattice plates – standard, microperforated or ribbed – for maximum flexibility in format changeovers; combined Vacuum-mechanical plates for special requirements or composite materials; dedicated plates for periodically recurring machining operations. Discover the wide range of solutions perfectly matched to our vacuum creation systems.

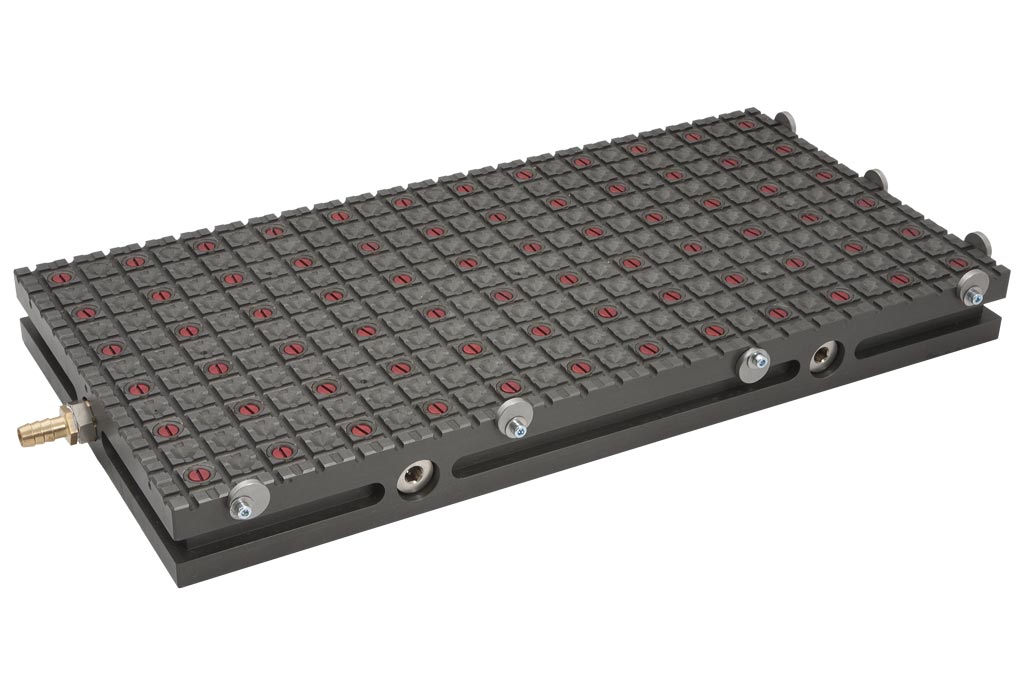

Standard vacuum plate

Ideal for

- fixing sheet metal and non-magnetic materials

- 5-sided machining

Materials

- steel

- aluminium

Totalblock Plate

Ideal for

- fixing sheet metal and non-magnetic materials

- even for 5-sided machining

Available with all Moretti mechanical fixing systems

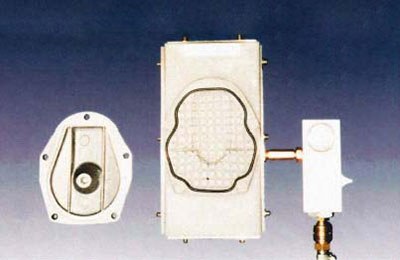

Microperforated and Ribbed Overlays

Ideal for

- accurate finishing

- precise measurement of the semi-finished products obtained using Standard Vacuum plates

Dedicated overlays

Ideal for

- customised machining

- subsequent machining of the semi-finished products obtained using the Standard Vacuum or Totalblock plates

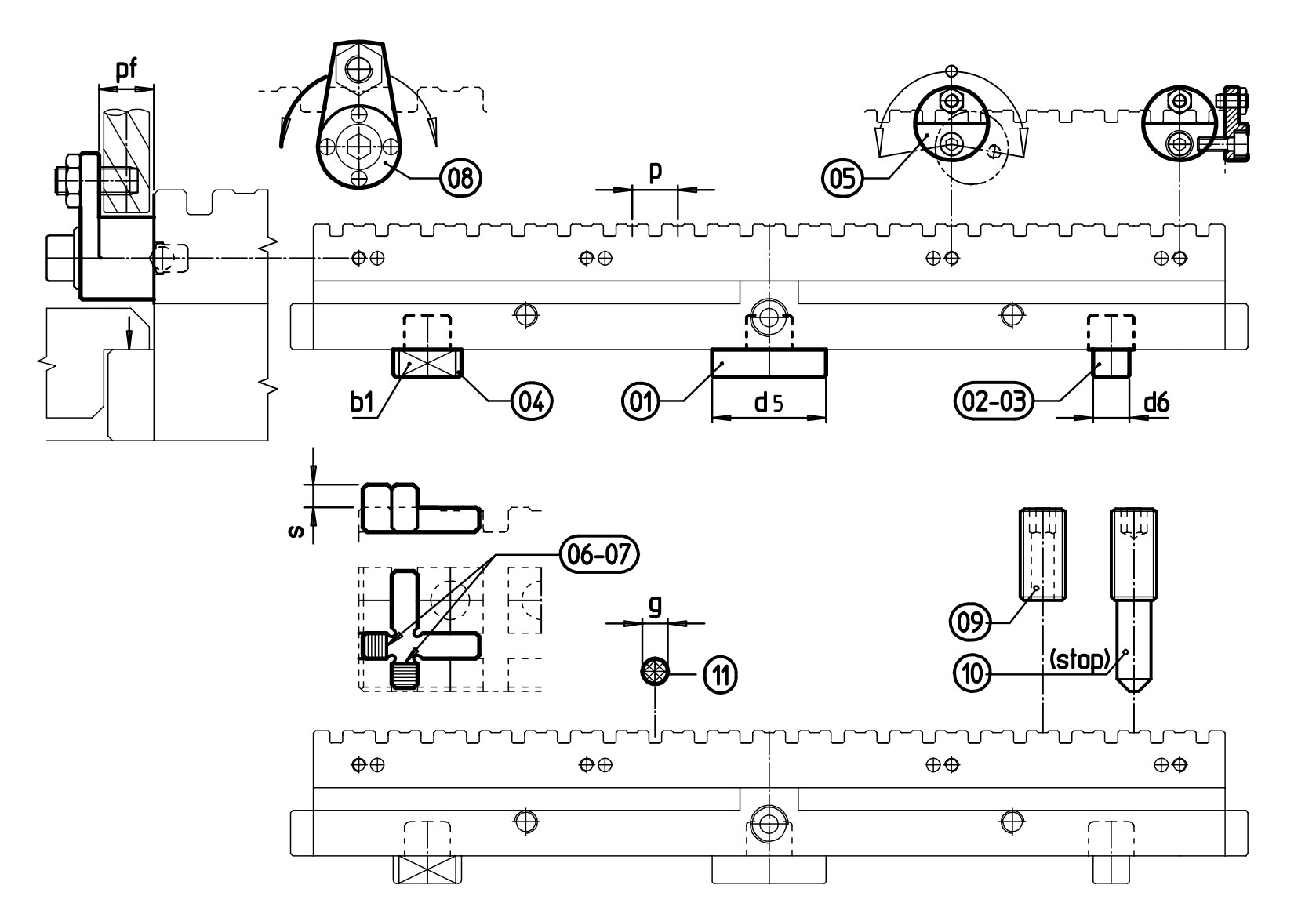

TECHNICAL DETAILS

Our Vacuum systems are turnkey solutions, which can operate as soon as they are connected to the power supply and compressed air. In the event of a power failure or lack of vacuum, the safety system sends an alarm signal to the PLC, stopping the process and preventing damage to tools. Virtually self-cleaning, they have very low maintenance requirements.

Our machines guarantee a high clamping force, which is a function of air pressure, vacuum and vacuum surface. To find out the tensile strength for different surfaces, please refer to the following table.

The pumps supplied on the standard stations have a flow rate of 15 m3/h but we can supply pumps for special applications with a flow rate of up to 65 m3/h.

Vacuum systems allow machining of parts of all shapes, with the only limitation of requiring a sufficient contact area between the workpiece and the plate (thereby excluding highly deformed surfaces).

Our experience enables us to suggest solutions for even the most complex machining operations with seemingly insurmountable problems, such as turning, cylindrical grinding, multi-pallet systems and flexible FMS lines.